dyson vacuum cleaner pdf

This interview was edited to fit a single page in the magazine. You can read the complete interview here. James Dyson famously went through 5,127 prototypes of his Dual Cyclone bagless vacuum cleaner before settling on the model that would make him a billionaire. His eponymous company now also makes bladeless fans and energy-efficient hand dryers, and operates in 49 countries. Dyson stepped down as chairman this year but remains the sole owner and chief engineer. HBR: How do you describe your profession? James Dyson: I’m sometimes called an inventor. But actually there’s no such thing. You’re an engineer or scientist who develops technology to create something new and better. I’m also keen on design; I started as a designer. I see them all as one, joined-up profession. You’ve said that your father’s death, in 1956, when you were nine, made you who you are today. Not having a father, particularly at that time, was very unusual. I was on my own. I can’t quite explain it, but I think subconsciously I felt a need to prove myself.

Something like 80% of British prime ministers since Walpole lost a parent before the age of 10. So there’s something in it. I’m certainly quite driven. What did your first boss, Jeremy Fry, teach you? When I went to work for him, I’d never designed a product.

dyson vacuum cleaners vs mieleI’d never sold anything.

vax carpet vacuum cleanerAnd he put me in charge of a company manufacturing a high-speed landing craft.

vacuum cleaners upright hooverSo he taught me that someone doesn’t have to grow into a job. If you allow them to make mistakes, they’ll learn extremely quickly. He also taught me to mistrust experience. He was far happier to have people working around him who had freshness and an unsullied approach.

When big manufacturers rejected the Cyclone, why did you press on and produce it yourself? I just felt that if I gave it up and did something sensible, I’d always regret it. As a user of vacuum cleaners, it was what I wanted. If the bags and loss of suction really annoyed me, surely they would annoy other people. You’ve launched a few related products, such as fans. Would you like to try more new things? Oh, no. I would have been quite happy to solve all the problems with vacuum cleaners for the rest of my life. Continuing to improve something—doing a better invention—is a much harder intellectual process than flitting from one thing to another. I’ve heard all Dyson employees have to assemble a vacuum cleaner on their first day of work. They might be nonexecutive directors, who are knights of the realm, but they still have to. It gives them confidence in the technology. They know what’s inside. And they keep the ones they build. It’s to emphasize that what we do is make products that people use.

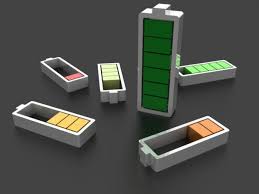

As an adviser to the British Conservative Party, you’re advocating new policies to boost innovation in the UK. How does education factor into that? If you look at schoolchildren doing a subject we have called design and technology, from age 10 to 14, they love it and they’re brilliant at it. But somehow that gets drilled out of them. And, really, the government is responsible. Britain produces far fewer engineers than the Philippines, Mexico, or Iran, not to mention India and China. So we’re not setting ourselves up very well for the future. And children are missing out on something they could have enjoyed. Exeter did a study that showed engineers are the happiest of all professions. A version of this article appeared in the July–August 2010 issue of Harvard Business Review.Last week, Dyson announced it was acquiring advanced lithium-ion battery producer Sakti3 for $90 million. The company now confirms it will use the Sakti3 technology for home appliances, rather than grid or vehicle applications.

“For the past five years, Dyson’s in-house battery team has been optimizing and developing battery technology for cordless machines and robots in its advanced battery labs at its Malmesbury headquarters,” said Dyson’s founder and chief engineer, James Dyson, in a press statement issued today. “They will now work with the team at Sakti3 to develop the prototype technology and incorporate it into new and existing technologies.” The acquisition follows Dyson’s £200 million (USD $310 million) spend on research and development of digital motors, “a technology that now powers our most successful machines,” said Dyson. “We will do the same with batteries.” Dyson says Sakti3’s solid-state technology could increase the energy density of today’s most advanced lithium-ion batteries while being smaller, safer, more reliable and longer-lasting. News of Dyson’s $90 million cash acquisition of Sakti3 emerged on the website Quartz last Thursday. According to the report, Dyson's and Sakti3’s boards approved the deal on September 25.

USA Today later reported that Dyson is planning to invest up to $1 billion in battery manufacturing facilities, possibly in Sakti3’s home state of Michigan. The acquisition has led to speculation that Dyson might be about to follow other technology players, such as Apple, into the electric-vehicle market. In March, Sakti3’s CEO, Ann Marie Sastry, told USA Today that home electronics would be the company’s most efficient path to market. However, she did say that vehicle battery development was ongoing. Logan Goldie-Scot, head of energy storage analysis at Bloomberg New Energy Finance, said this was unlikely in the short term under Dyson. “To date, the company has seemed to be only interested in using [the technology] for its home appliances,” he said. “It would be a pretty major shift for the company to try to get into EVs and grid-scale [storage] from here.” It is believed that Sakti3’s technology, which was demonstrated to Barack Obama in June, is still years from commercialization.

And there is some discrepancy over how much money it has taken to get this far. Up to the sale, Sakti3 had attracted $50.2 million in funding over six rounds, according to CrunchBase. That's consistent with GTM Research’s estimate of $47 million, along with a $3 million grant in 2012. Bloomberg New Energy Finance, however, cited $27 million of disclosed investments since 2008. And sources at Sakti3 said fundraising had already reached $12 million in 2010, before Series B funding had finished. The latest funding series, in March, included $15 million from Dyson, along with $5 million from General Motors and Khosla Ventures. Khosla was the first major investor in Sakti3, pumping $2 million into the startup in 2009. Khosla Ventures founding general partner, Samir Kaul, is on the board of directors at the battery developer. Coincidentally, Khosla exited from one of its other solid-state battery developer investments only seven weeks ago, in a transaction that was also first reported by Quartz.

The sale of Seeo to Bosch in August, for an undisclosed figure, was much more closely tied to the automotive market. Like Sakti3, Seeo’s technology is said to increase lithium-ion energy density by between 50 percent and 100 percent. That could significantly boost the operating range of electric cars. Doubts surround the viability of the technology, however. As previously reported by GTM, Seeo’s batteries had undergone a change of chemistry during development and were said to require an operating temperature of 80 degrees Celsius. On top of that, Samsung sold its stake in the company. The final terms of the sale were never disclosed -- indicating a low-value asset sale rather than a cork-popping VC success. Among other Khosla-backed solid-state battery makers, QuantumScape was also supposed to be courting institutional investor interest after Volkswagen took a 5 percent stake in the company last December. The carmaker was said to be forging ahead with QuantumScape’s technology by the middle of this year.