vacuum cleaner motor turbine

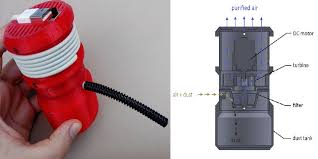

Loann Boudin is a French student and dedicated maker, and he decided he needed a mini USB vacuum cleaner, but rather than take the obvious route and head to the electronics store to purchase one, he decided to design and 3D print one himself.According to Boudin, spending hours making things on his desktop from plastic, wood and various electronic parts made rather a mess.“I needed a small and efficient device to clean the mess, so I decided to design and make my own,” Boudin says. “This mini vacuum cleaner is very helpful. I can now clean my laptop keyboard, my desk, and all the small fragile items I collect.”So with a small, RE-140 DC motor commonly found in toys, an old USB Apple cable from an iPhone 5, a 6 x 12 mm switch, some LEGO pieces, a tea bag for use as a filter, and a 3D printer, Boudin set to work.He says the most critical part of a vacuum cleaner is the turbine, so after examining several turbines from handheld vacuum cleaners left over in his toolbox, he ultimately used SolidWorks to design one that would fit his application and design.

His mini USB vacuum cleaner includes just seven printed parts: a top cover, a motor holder, a pair of turbine parts, a turbine cover, a filter holder, and a dust collection tank.Boudin says that, while he doesn’t have a 3D printer of his own, he did some research into the 3D printing service 3D Hubs and found a hub just 1.4 miles from his home. Rather than use the local hub, though, he decided to take advantage of a Prusa I3 3D printer owned by an electronics association he belongs to. He used Repetier and Slic3r to drive the 3D printer.What Boudin came up with is an amazingly professional looking device. And as an added bonus, if you decide to take on the task of building one yourself, he’s provided all the necessary files to do just that on a highly detailed Instructables project.From gathering supplies to 3D printing the key components to disassembling a tea bag for use as the filter, Boudin’s Instructable will lead you through the final assembly. Once everything is put together, just plug it in via USB and you have some concentrated cleaning power ready!

Will you build yourself a 3D printed, USB powered mini vacuum cleaner based on Loann Boudin’s design? Have you ever used 3D printing to design a practical item for use around your home? OERTZEN - NT 90-3 - Wet/Dry Vacuum Cleaner

steam vacuum cleaner comparison Compact overview: OERTZEN - NT 90-3 - Wet/Dry Vacuum Cleaner - 3240 W suction power - 90 L dirt container - wet and dry vacuum cleaner

samsung upright vacuum cleaner cena OERTZEN NT 90-3Wet/dry vacuum cleanercontainer made of high impact PE 3 suction turbines with separate motor coolingfloat valve for suction power off (prevents water from penetrating turbines)container volume 90 l, useful capacity 75 ltextile filter (for dry cleaning)

vacuum cleaners plant city fl

suction hose 40 mm diameter, length 2.5 msuction pipe (3 parts)floor water nozzlefloor brush nozzlefloor carpet nozzlejoint nozzlebrush nozzleelectric cable (10 m) with plugOrder-number: 10.805.093 Product request » Suction turbine / number 430 x 550 x 910 mm technical data are subject to alterations OERTZEN - APS 30 - Spray Extraction Vac OERTZEN - NT 43 - Wet/Dry Vacuum Cleaner OERTZEN - NT 90-2 - Wet/Dry Vacuum Cleaner OERTZEN - NT 90-3 - Wet/Dry Vacuum Cleaner OERTZEN - WPS 90 - Hydro Extraction Vac Does this device not yet really come up to your demands? Please start a new inquiry! Wet and dry vacuum cleaner spray extraction cleaner 1080 W suction power 2160 W suction power 3240 W suction power 30 L dirt container 43 L dirt container 90 L dirt container von Oertzen GmbHFerdinand-Harten-Straße 1022949 Ammersbek / GermanyTel: +49 40 604 11-0Fax: +49 40 604 11 49E-mail: info@oertzen-gmbh.de For the time being no products have been viewed!

© 2016 by von Oertzen GmbH page powered by gimmixx New MediaThey normally sell for $100 and up, but Dremel has found a way to make its rotary multi-tools a lot cheaper for anyone who already has a workshop full of equipment. Instead of having its own motor inside, the company’s new VRT1 is powered by the suction from a vacuum. Available for just $30 including a small assortment of accessories, inside the VRT1 you’ll find a turbine that’s powered by the suction from a wet/dry shopvac that you connect to the end of the rotary tool with its standard hose. As an added bonus, the attached vacuum also serves to suck up dust and debris while you’re working with the tool. So why would you ever opt for a standard Dremel rotary tool then? While the company claims the VRT1 can still hit speeds of up to 35,000 revolutions per minute, the torque on this tool will still pale in comparison to a Dremel with its own electric motor inside. So if you’ve got some heavy grinding or sanding to do, and don’t have access to a jet engine to provide a significant source of airflow, you’ll probably find its performance lacking.

But that’s why Dremel is selling it so cheap.Turbines have awesome power in a small package. This one spins up to 60,000 rpm using the airflow of a standard vacuum cleaner, sounds like a 747 taking off, produces amazing power, and sucks up its own dust! This is an opportunity for someone to make a successful product. I have no commercial interest, and would be delighted if anybody developed it further. A good start would be to source a batch of shafts and spacers for people to experiment with. The spinning top is an simpler project, also there is a small hand-held turbine rotor just for fun. Warning - High rpm - USE EYE PROTECTION AT ALL TIMES To have some fun right now, make the hand-held rotor, use a 4mm bolt or nail, and make magic whizzing noises with your vacuum cleaner. The Spinning Top requires a few bits, but no special machining. DO NOT PRINT the body, I purchased a 2" plastic wheel which has the strength for the high rpm. The shaft is 5mm all-thread or bolt, and the socket is a 5mm Philips head screw drilled out.

The Turbine Dremel-type tool is awesome, but does require proper bearings and an accurate machined shaft. High speed requires excellent engineering. , check the rpm rating for the type you find. The shaft could be just 6mm rod if you don't want power out, but the Dremel style tool head requires a tricky 9/32" x 40tpi thread for the nut, or may be metric for other brands. The design is a 2-stage axial turbine, with 2 stators to twist the air, and 2 rotors to deliver the power. I considered a radial inflow design like the auto turbo, but the axial one is more compact. The speed and power is amazing. It was only when doing the video that I realised it was doing nearly twice the speed of my Dremel, really scary! The rotor and blade design is my first attempt, it is powerful enough without any optimisation. I should change the pitch of the rotors to reduce the speed to match other rotary tools. The tool is great for cutting composites, as most of the dust is sucked up, instead of the Dremel's cooling fan which blows it everywhere including inside my goggles.